Consumer demand for large-size TVs with superior picture quality sparked development of next-generation display technologies. Recent examples include 65” and 77” OLED TVs, as well as Blue OLED TVs fabricated using quantum dot color conversion (QDCC) technology. Not surprisingly, manufacturing the new displays involves a complex production process.

Inkjet is already a proven production solution for OLED thin film encapsulation (TFE), so it was natural for Kateeva to extend inkjet’s capabilities to address pixel-level printing on RGB and QDCC layers. As a scanning technology, inkjet is inherently scalable, which makes it an ideal manufacturing solution for large-size displays. Since inkjet is known for its yield and cost benefits, it offers an appealing alternative approach to costly vacuum thermal evaporation (VTE) and photolithography processes.

The standard glass sizes utilized to mass produce large-size displays are Gen 8.5 and Gen 10.5. Gen 10.5 glass can hold 6 x 75” TV panels or 8 x 65” TV panels (figure 1).

Figure 1: Glass size up to Gen 10.5

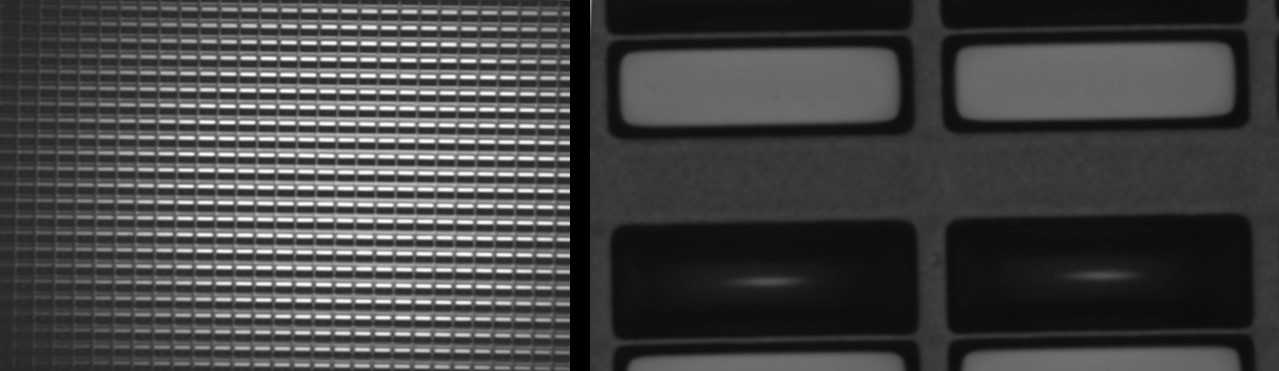

For inkjet to process a single 65” OLED panel, high numbers of ink drops in the pico-liter (pl) range must be deposited with flawless accuracy into millions of pixel wells. This is equivalent to placing 3~5 drops of ink into 24+ million pixels. For a single 4K TV display, that is approximately 100 million drops (figure 2) and a master glass can hold up to six of those panels to be printed at once. Also, for mass production, throughput must be high – just minutes per glass with multiple panels.

Figure 2: Pixel printing images

With ultra-high-resolution displays, the pixel size is tiny, while pixel width (~40um) is extremely narrow. Filling the pixel wells requires a miniscule drop size. For large-gen printers, this means that the print heads must jet tiny drop volumes (1pl~6 pl). For certain display layers, the printer must contain over 50 print heads with >1000 nozzles per head—a much higher count than what is required for small-size glass. To scale and address the drop size and volume imperatives, Kateeva developed Smart Mixing™ — a sophisticated print algorithm that drops the exact volume into every pixel well with extreme precision.

At the same time, Kateeva-developed motion systems work in concert to deposit the tiny drops into target locations. The systems include a “floating stage” and print head assembly components that are precisely aligned on a single solid granite stage. This minimizes vibration risk and provides the straightest plane possible.

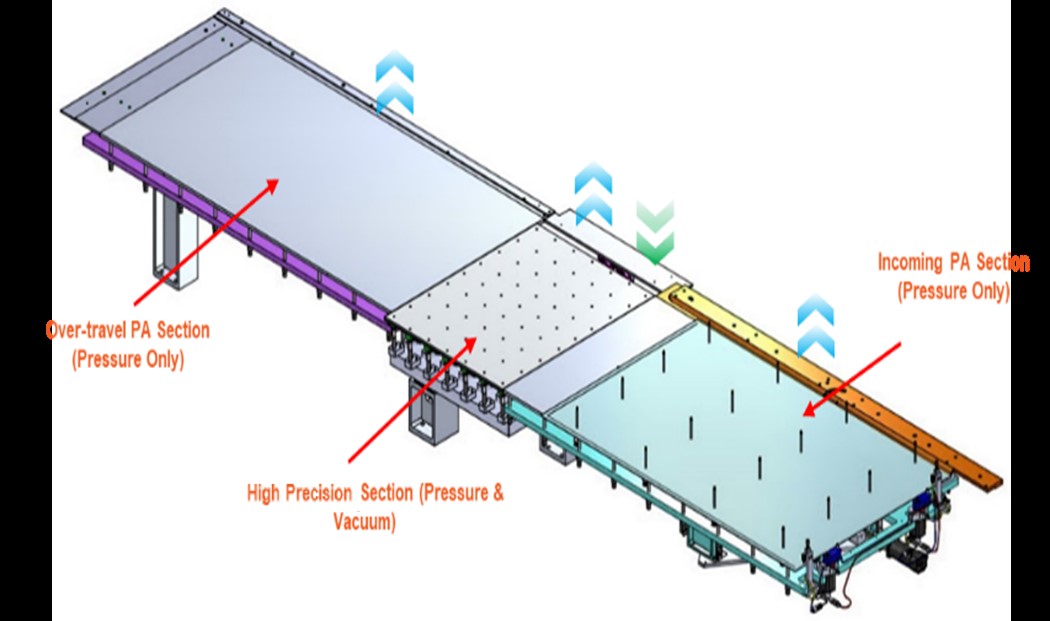

The “floating stage” uses air or nitrogen pressure to levitate and smoothly transfer the large glass panels from inlet to outlet during printing (figure 3). A vacuum system controls the fly height (~30um) between the stage and the floating glass. This helps maintain a correct distance between the print head nozzle plate and the glass surface throughout the printing process.

Figure 3: Floating stage concept

While the vacuum and pressures are critical elements that control and maintain straightness throughout the print pass, the weight and thickness of the glass govern the behavior of the substrate during the floating process. The floating table is carefully measured and fine-tuned to minimize the curves/bowing effect and achieve maximum flatness. Glass convex and concave effects can occur when the balance between pressure and vacuum is not achieved.

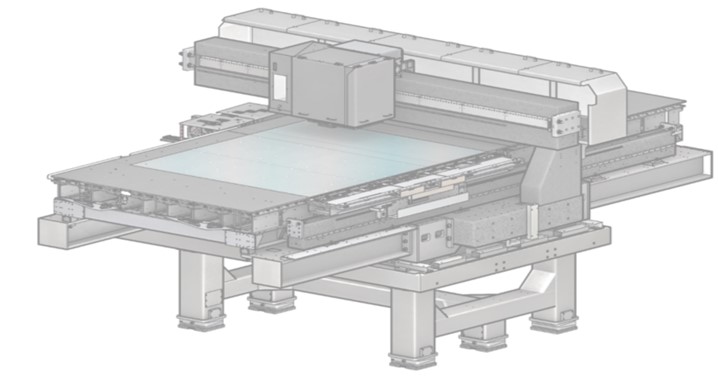

Finally, for the substrate to move smoothly, a vacuum gripper located under the edge of the glass provides forward and reverse bidirectional movements. The gripper is engineered to sustain the acceleration of large-gen glass sizes at print-pass speeds of over 500mm/sec. (figure 4)

Figure 4: Vacuum pressured gripper with gripped G8.5 glass

The combination of hardware and software innovations propelled Kateeva’s TFE systems into the leadership position for mobile phone production. Now, Kateeva is scaling its latest inkjet technology to large panel production for next generation television displays.

简体中文

简体中文 한국어

한국어 English

English