In the decades since Steve Van Slyke* and Ching W. Tang co-invented the OLED device, OLED technology has steadily transformed the display industry. Today, the technology is enabling foldable displays.

The journey to foldable displays involved relentless materials, process and equipment innovations. First came the rigid OLED smartphone that dazzled consumers with unprecedented contrast and color quality. Shortly after, smartphones enabled by flexible OLEDs were released, featuring elegantly curved and bezel-less screens that greatly expanded the viewing real estate.

Now, manufacturers are stretching OLED technology to fulfill an even higher promise: displays that fold.

This year, the foldable smartphone is available for order. Early forecasts predict that 5+ million units will ship to consumers next year. By 2023, the number will soar to 68 million units, says Display Supply Chain Consultants.

Thin Film Encapsulation: The Enabling Barrier

Innovative encapsulation technologies helped pave the way for foldable displays. OLED materials are inherently vulnerable and susceptible to degradation when exposed to contaminants like water and air. To protect the OLED layers, an encapsulation barrier is implemented. The first mobile OLEDs were encapsulated with rigid glass. But flexible OLEDs have different encapsulation requirements. Glass was no longer an option and was replaced by thin film encapsulation (TFE).

Kateeva pioneered the YIELDjet™ FLEX inkjet printing system to enable OLED TFE at a cost that could drive mass consumer adoption. Since its introduction in 2014, the tool has been used to manufacture more than 400 million flexible OLED displays, making it the market-leading mass production equipment solution for OLED TFE. New-generation smartphones will be available in a variety of foldable and rollable form factors – enabled by Kateeva’s TFE technology.

Inkjet: Proven Printing Platform for OLED TFE

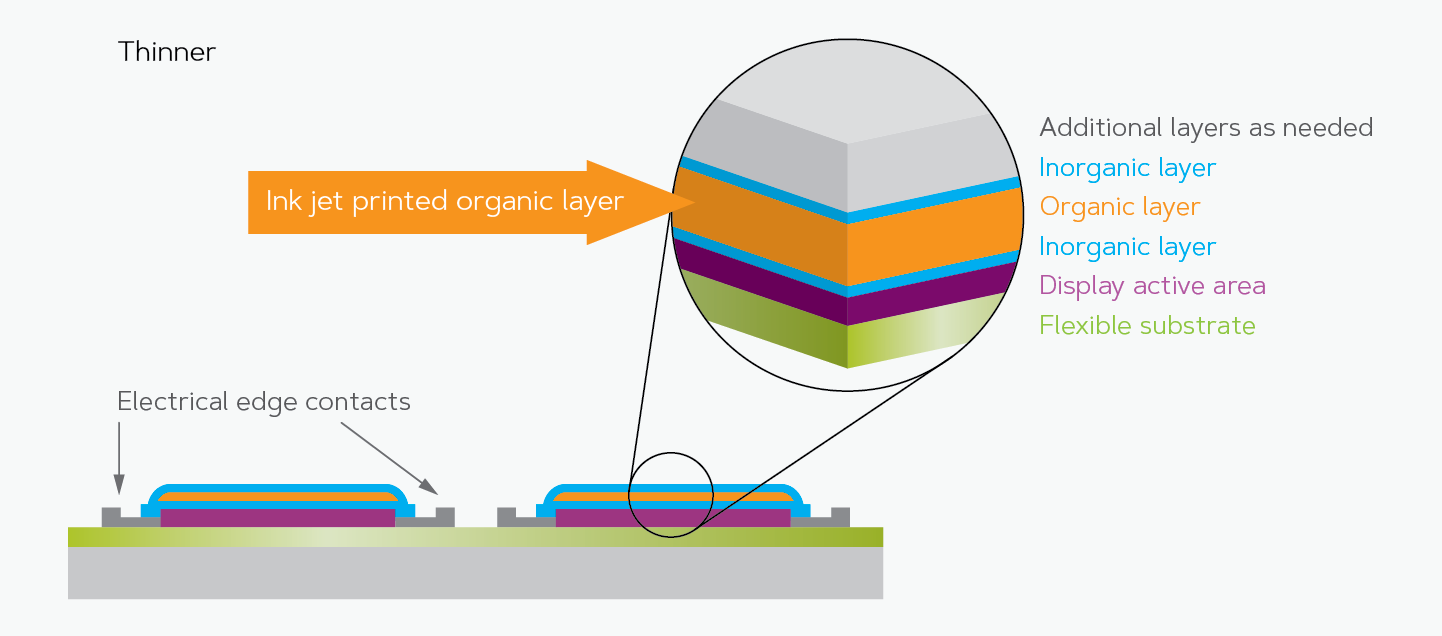

A TFE stack is typically comprised of alternating organic and inorganic layers. The imperatives for mass-production include a processing environment that is oxygen and moisture-free, as well as excellent film uniformity, ultra-low particles, and high productivity. Before Kateeva, the conventional deposition approach was vacuum flash evaporation, but this technology was plagued by low material utilization efficiency and could not achieve high yields in mass production.

Inkjet-printed organic layer in TFE stack

Kateeva’s YIELDjet FLEX system combines nitrogen integration, a floating stage, UV curing and smart mixing technology to create a clean, inert environment for precision deposition. When deployed for OLED TFE, this solution significantly reduces device thickness and improves overall yield, while boosting flexibility and transparency. These advantages become even more important for displays featured in foldable smartphones, which tend to be larger (>7”) than displays used in earlier OLED-enabled smartphones (5-6”).

Relentless Innovation Paved the Path to Foldable

The first foldable prototypes were produced thanks to advancements in materials and manufacturing technologies and processes. To drive mass adoption, the new technologies must be implemented at an acceptable yielded cost. This includes TFE. With that goal, Kateeva continues to improve its inkjet platform with new hardware and software innovations to enable films that are robust, uniform and defect-free. Our FLEX Plus 1 , for example, is capable of printing a TFE layer that is thinner than any previously achieved, with excellent film uniformity, and free of defects, while expanding the process window available for printed TFE layers.

The collective innovation of companies in the display ecosystem has created a viable path to mainstream foldable displays. As a pioneer of OLED TFE equipment, Kateeva is helping display manufacturers scale and support the emerging foldable display technologies.

*Steve Van Slyke is CTO Emeritus at Kateeva

简体中文

简体中文 한국어

한국어 English

English